Hi guys, my first post. Boy this site sure would of helped back in 1999 when I built my "salad bowl" bench.

My current thoughts are to build a sealed cylinder block and pull air out the oil pan &/or exhaust collector using 4" pipe coming off the vacuum and pressure chambers in the bench wit a 2" pitot tube, mainly to test intake & exhaust manifolds.

Any ideas on how big (volume) the oil pan would need to be.

Ideas on where to take the static pressure drop when pulling air out the exhaust without a settling chamber or is the 4" pipe going to be enough to calm the air down.

Thanks Chip

Air out block & header collector

8 posts

• Page 1 of 1

Pulling air out of an exhaust port certainty works, and can give very valid measurements. The big disadvantage of doing it that way, is you cannot then work with an open exhaust port to study or probe flow.

For practical reasons it is a lot nicer to blow air into a cylinder bore fixture up from below. Then you can study the air coming out of the exhaust port, even with a short header tube stub attached.

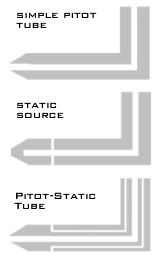

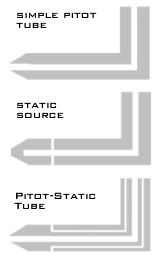

Measuring static air pressure in a very fast moving air stream can be difficult. By far the best (and proper) way is to build a pitot static probe. They are very easy to make, and completely solve the problem.

These work well enough, and accurately enough for a pressure altimeter to be dependable in a fast flying aircraft. It is also a great way to measure static pressures in your flow bench which probably has some very angry air in there.

For practical reasons it is a lot nicer to blow air into a cylinder bore fixture up from below. Then you can study the air coming out of the exhaust port, even with a short header tube stub attached.

Measuring static air pressure in a very fast moving air stream can be difficult. By far the best (and proper) way is to build a pitot static probe. They are very easy to make, and completely solve the problem.

These work well enough, and accurately enough for a pressure altimeter to be dependable in a fast flying aircraft. It is also a great way to measure static pressures in your flow bench which probably has some very angry air in there.

Also known as the infamous "Warpspeed" on some other Forums.

- Tony

- Posts: 824

- Joined: Sat Dec 03, 2005 12:34 pm

- Location: Melbourne, Australia

Thanks for your responses, it's never as easy as it looks on paper is it.

Both seem like simple solutions, thanks.

Tony, just so I'm clear on this." By far the best (and proper) way is to build a pitot static probe. They are very easy to make, and completely solve the problem."

This would work for the test pressure, ie:28"

thanks Chip

Both seem like simple solutions, thanks.

Tony, just so I'm clear on this." By far the best (and proper) way is to build a pitot static probe. They are very easy to make, and completely solve the problem."

This would work for the test pressure, ie:28"

thanks Chip

- Chipster

- Posts: 3

- Joined: Mon Nov 19, 2007 5:24 pm

A pitot static pressure source is quite simple to make, just a very small bore pipe with the blunt rounded end pointing directly into the airflow. Block the end with an aerodynamically smooth round blob of solder (or epoxy), and drill several pin holes at least several pipe diameters back from the nose, as in the second picture:

More here:

Just mount the static pressure measuring pitot probe in the location where you wish to measure test pressure. It will measure static air pressure in either still air, or in a very fast moving airstream and produce an accurate steady static pressure reading even at very high air velocities.

More here:

Just mount the static pressure measuring pitot probe in the location where you wish to measure test pressure. It will measure static air pressure in either still air, or in a very fast moving airstream and produce an accurate steady static pressure reading even at very high air velocities.

Also known as the infamous "Warpspeed" on some other Forums.

- Tony

- Posts: 824

- Joined: Sat Dec 03, 2005 12:34 pm

- Location: Melbourne, Australia

I built an "Aluminum Block (that resembled an engine's rough dimensions) out of plate aluminum for a test fixture one time for some Ford Motor Company Air Flow testing work. It worked just fine.

Biggest advantage was it was a lot lighter than a real cast iron engine block. It had removable "Block Decks with liners" so that I could test different bore spacing configurations. Volume of the engine will be ok for the plenum size, I think.

How are you planning on reading the flow from/in the intake manifold?

Smokey Yunick used a Laminar Flow Element to read the flow going to the carb -> Intake -> head -> block. So did Larry Widmer see links:

Link to "The Old One"

The "Soft Head"

Tom V.

Biggest advantage was it was a lot lighter than a real cast iron engine block. It had removable "Block Decks with liners" so that I could test different bore spacing configurations. Volume of the engine will be ok for the plenum size, I think.

How are you planning on reading the flow from/in the intake manifold?

Smokey Yunick used a Laminar Flow Element to read the flow going to the carb -> Intake -> head -> block. So did Larry Widmer see links:

Link to "The Old One"

The "Soft Head"

Tom V.

- ThomasVaught

- Posts: 80

- Joined: Fri Jul 06, 2007 9:06 pm

Thanks for the link and the responses. Worlds slowest typist here so please be patient.

Ok let me try to explain the air flow path.

Intake manifold test: air into carb and/or carb adapter and/or intake bolted to pair of "master reference heads" on a sealed small Chevy block, pull air out oil pan with 4" pvc into 2" averaging flow element back into 4" pvc into the vacuum side of my "salad bowl/msd" bench next to the air relief door. measure flow individually on each cylinder.

Test pressure drop pickup "hiding" in the main oil gallery via the 1/4' pipe plug in the back of the block, pressure drop set by opening the valve normally used for intake testing to bleed air out the top of the msd bench(normal cylinder head adapter opening). Hoping I can use my existing meters and lengthen the hoses. 32" vertical, 12" inclined and make a inch scale to clip over the % scale.

I feel pretty comfortable with this, tell me where I went wrong or if you guys have better ideas.

Exhaust side: same block & heads with test cast iron exhaust manifolds / exhaust system bolted on. pull air out stub exhaust pipe or 2 into 1 collector.(usually3" sometimes3 1/2") same pvc set up connected to outlet of exhaust and back to bench. test each cylinder individually. I probably don't have enough motors to test all 8 at the same time.

I was struggling with where to pick up the test pressure for the vertical during exhaust testing.

Looking at Tony's solution I wonder if the vertical and inclined could be T'd together in the flow element or is it better further upstream in the 4"(closer to the exhaust outlet).

Pictures of Smokey and Larry Widmer stuff is what got me thinking about this.

Most of what I build is 2bbl carb, stock cast iron intake and cylinder head dirt track engines, some cast iron exhaust, some with headers.

I was looking for some thing other than hanging a heavy iron intake off a head on the flow adapter.

Thanks Chip

Ok let me try to explain the air flow path.

Intake manifold test: air into carb and/or carb adapter and/or intake bolted to pair of "master reference heads" on a sealed small Chevy block, pull air out oil pan with 4" pvc into 2" averaging flow element back into 4" pvc into the vacuum side of my "salad bowl/msd" bench next to the air relief door. measure flow individually on each cylinder.

Test pressure drop pickup "hiding" in the main oil gallery via the 1/4' pipe plug in the back of the block, pressure drop set by opening the valve normally used for intake testing to bleed air out the top of the msd bench(normal cylinder head adapter opening). Hoping I can use my existing meters and lengthen the hoses. 32" vertical, 12" inclined and make a inch scale to clip over the % scale.

I feel pretty comfortable with this, tell me where I went wrong or if you guys have better ideas.

Exhaust side: same block & heads with test cast iron exhaust manifolds / exhaust system bolted on. pull air out stub exhaust pipe or 2 into 1 collector.(usually3" sometimes3 1/2") same pvc set up connected to outlet of exhaust and back to bench. test each cylinder individually. I probably don't have enough motors to test all 8 at the same time.

I was struggling with where to pick up the test pressure for the vertical during exhaust testing.

Looking at Tony's solution I wonder if the vertical and inclined could be T'd together in the flow element or is it better further upstream in the 4"(closer to the exhaust outlet).

Pictures of Smokey and Larry Widmer stuff is what got me thinking about this.

Most of what I build is 2bbl carb, stock cast iron intake and cylinder head dirt track engines, some cast iron exhaust, some with headers.

I was looking for some thing other than hanging a heavy iron intake off a head on the flow adapter.

Thanks Chip

- Chipster

- Posts: 3

- Joined: Mon Nov 19, 2007 5:24 pm

Ok, maybe I'm missing something here . . . but why would you not just run a 4" hose from your oil pan to an adapter on the top of your flowbench (using the existing flowbench gages)?

Again I might be missing something . . .

Again I might be missing something . . .

"There is no more formidable adversary than one who perceives he has nothing to lose." - Gen. George S. Patton

- bruce

- Site Admin

- Posts: 1638

- Joined: Sun May 09, 2004 12:17 pm

8 posts

• Page 1 of 1

Who is online

Users browsing this forum: No registered users and 1 guest