You can also see my attempt at making a bobweight for crank balancing. It needs some final changes before I actually test balance anything

My latest project

9 posts

• Page 1 of 1

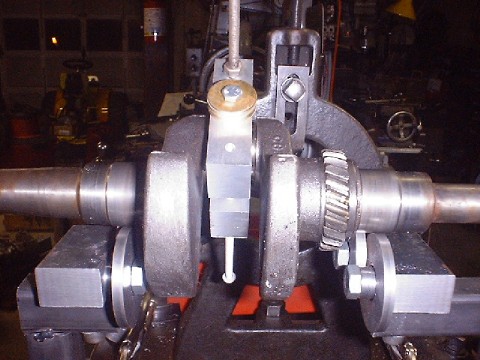

This is a small static balancer I built to help me balance rotating parts for my shop. This is my first try and have already found some changes I plan on making on the next "upgrade' for now I'll work with what I built. Its better than what I was doing before, which was nothing . . .

You can also see my attempt at making a bobweight for crank balancing. It needs some final changes before I actually test balance anything

You can also see my attempt at making a bobweight for crank balancing. It needs some final changes before I actually test balance anything

- 98-1074649673

Bruce;

For the crankshaft shown in the picture, you will be better off using the conrod & bearings with some dry lube on the journal for balancing purposes, you have to weigh the big end with bearings & then the small end of the rod with bush or whatever & then the piston with rings & the gudgeon pin. From this you can work out a suitable % of bob weight which will be a small container full of nuts or something suspended by a wire hook from the small end.

This crankshaft should be in perfect static balance before trying anything else, when you have your calculated bob weight % hanging from the smallend the static balance will be found when the rod journal is upright vertical & the conrod will be hanging straight down vertical between the counterweights.

When this balance is found you will be able to rock the crank & it will return the rod journal ( exactly) to centre top.

I have some of my old bob weight calculations SOMEWHERE if i can find them i will post them, they will help you i'm sure!!!!

One other thing, i think you will find it will be better to do some weight reduction from the counter weights which will help enormously!!!

Do not do this until you know what your balance is going to be though!!!

Hope this helps!!!

For the crankshaft shown in the picture, you will be better off using the conrod & bearings with some dry lube on the journal for balancing purposes, you have to weigh the big end with bearings & then the small end of the rod with bush or whatever & then the piston with rings & the gudgeon pin. From this you can work out a suitable % of bob weight which will be a small container full of nuts or something suspended by a wire hook from the small end.

This crankshaft should be in perfect static balance before trying anything else, when you have your calculated bob weight % hanging from the smallend the static balance will be found when the rod journal is upright vertical & the conrod will be hanging straight down vertical between the counterweights.

When this balance is found you will be able to rock the crank & it will return the rod journal ( exactly) to centre top.

I have some of my old bob weight calculations SOMEWHERE if i can find them i will post them, they will help you i'm sure!!!!

One other thing, i think you will find it will be better to do some weight reduction from the counter weights which will help enormously!!!

Do not do this until you know what your balance is going to be though!!!

Hope this helps!!!

- willeng

- Posts: 14

- Joined: Fri Feb 13, 2004 1:59 am

Bruce:

I forgot to mention, when balancing these cranks it is a very delicate proceedure & there can be no friction at all in any of the fittings etc.

I know you have already made your setup but might i suggest that two parallel perfectly level knife edge offer the best way to static balance the cranks-----no friction!!

Hope this helps!!!

I forgot to mention, when balancing these cranks it is a very delicate proceedure & there can be no friction at all in any of the fittings etc.

I know you have already made your setup but might i suggest that two parallel perfectly level knife edge offer the best way to static balance the cranks-----no friction!!

Hope this helps!!!

- willeng

- Posts: 14

- Joined: Fri Feb 13, 2004 1:59 am

Why would I not want to use a bobweight? The bobweight you see allows me to add weight in the form of washers, right now it was just "slapped" together for pic purposes for another forum I visit. I'm adding stainless steel threaded studs today and some wing nuts so its easier to add and change weights.

The rollers spin extremely freely and the crank will spin and spin in this setup. Your idea of knife edges is a valid one but after alot of research on the net on static balancing I deceided this was the way to go for my particular application and flexiablity. I plan on rebuilding this setup after some intial design flaws I don't like now that its done. Mainly the ability to square everything up. My next set of bearings will be ABEC 5 or 7's and the wheel will be thinner so the whole assembly is smaller in width and the wheels will be larger in dia .

I already know what range % of weight I need to work within for my single cylinder crank assemblies. I feel only time on the dyno will give me working numbers though, which means alot of R&D and I'm wondering if getting that accurate will mean all that much in performance? Heck I don't even balance them now so this is a step up in the right direction for me. Thanks for the offer of calculations though, I need to setup a spreadsheet to do the math for me (geez another project). My plan on this particular crank will be to balance the parts to the crank instead of the crank to the parts, don't want to mess up a crank on my first go-round.

Please do not take my response back to your ideas in anyway as "I know what I am doing leave me alone" I value any and all input and thats why I post my projects for critique. Feedback is the GREAT thing about the net!!! Someone else may have one little tip that someone else never thought of . . . I always enjoy healthy discussions

The rollers spin extremely freely and the crank will spin and spin in this setup. Your idea of knife edges is a valid one but after alot of research on the net on static balancing I deceided this was the way to go for my particular application and flexiablity. I plan on rebuilding this setup after some intial design flaws I don't like now that its done. Mainly the ability to square everything up. My next set of bearings will be ABEC 5 or 7's and the wheel will be thinner so the whole assembly is smaller in width and the wheels will be larger in dia .

I already know what range % of weight I need to work within for my single cylinder crank assemblies. I feel only time on the dyno will give me working numbers though, which means alot of R&D and I'm wondering if getting that accurate will mean all that much in performance? Heck I don't even balance them now so this is a step up in the right direction for me. Thanks for the offer of calculations though, I need to setup a spreadsheet to do the math for me (geez another project). My plan on this particular crank will be to balance the parts to the crank instead of the crank to the parts, don't want to mess up a crank on my first go-round.

Please do not take my response back to your ideas in anyway as "I know what I am doing leave me alone" I value any and all input and thats why I post my projects for critique. Feedback is the GREAT thing about the net!!! Someone else may have one little tip that someone else never thought of . . . I always enjoy healthy discussions

- 98-1074649673

Bruce:

I understand what yor saying & no offence taken, the reason i made the suggestions is that i have built many single cylinder race engines & have made many high performance crankshafts for these applications.

Many of them 15-1 comp methanol engines that run to 10,000 rpm without failure.

The basic problem with trying to balance the single cylinder cranks is that it is a precise art more that anything & when you consider that a 1/8" dia hole of 1/8" depth can either add a % of negative or positive balance to a well balanced crank is a scary thought.

The reason to use the conrod & the bob weight container is that the conrod will always have it's weight perpendicular & therefore there is less chance of anything disrupting the fine balance that is needed.

ie

With the bob weight shown in the picture it is possibe to have a lot more weight to one side than the other considering we are talking about minute amounts of weight & is nearly impossible to get right, because the centre of the weight needs to be perfectly perdendicular at all times, this happens automatically with the normal proceedure of balance using the conrod & bob weight container.

When you balance the cranks correctly it will make a marked improvement to the way the engine performs & also to bearing life etc.

It is possible to reduce the reciprocating mass by a great deal also adding response to the engine. Once this is done you will be able to decrease the weight of the counterweights considerably all adding to perfomance gains!!

It is better to run rotating & reciprocating weights as low as possible but still keep it reliable.

Honestly the best way is the tried & true way of gaining static balance & you will see what i mean if you try it, the smallest amount of modelling clay placed in different positions on the crank will show a dramatic change in balance & this shows you were the weight needs to be remove from.

One other suggestion, i would use a 1 to 1.5% positive overbalance on the crank shown & i believe it will net you some good results.

It's a fine line this balancing thing----good luck with it!!

Hope this helps!!

I understand what yor saying & no offence taken, the reason i made the suggestions is that i have built many single cylinder race engines & have made many high performance crankshafts for these applications.

Many of them 15-1 comp methanol engines that run to 10,000 rpm without failure.

The basic problem with trying to balance the single cylinder cranks is that it is a precise art more that anything & when you consider that a 1/8" dia hole of 1/8" depth can either add a % of negative or positive balance to a well balanced crank is a scary thought.

The reason to use the conrod & the bob weight container is that the conrod will always have it's weight perpendicular & therefore there is less chance of anything disrupting the fine balance that is needed.

ie

With the bob weight shown in the picture it is possibe to have a lot more weight to one side than the other considering we are talking about minute amounts of weight & is nearly impossible to get right, because the centre of the weight needs to be perfectly perdendicular at all times, this happens automatically with the normal proceedure of balance using the conrod & bob weight container.

When you balance the cranks correctly it will make a marked improvement to the way the engine performs & also to bearing life etc.

It is possible to reduce the reciprocating mass by a great deal also adding response to the engine. Once this is done you will be able to decrease the weight of the counterweights considerably all adding to perfomance gains!!

It is better to run rotating & reciprocating weights as low as possible but still keep it reliable.

Honestly the best way is the tried & true way of gaining static balance & you will see what i mean if you try it, the smallest amount of modelling clay placed in different positions on the crank will show a dramatic change in balance & this shows you were the weight needs to be remove from.

One other suggestion, i would use a 1 to 1.5% positive overbalance on the crank shown & i believe it will net you some good results.

It's a fine line this balancing thing----good luck with it!!

Hope this helps!!

- willeng

- Posts: 14

- Joined: Fri Feb 13, 2004 1:59 am

Have you guys ever seen a balancing machine built using a set of points an d a strobe(timing light) I found a diagram on the net a long time ago. It may be kinda oldschool, but its still interesting to see. If I can find a link to it I will post it...I had a thought on the bearings for the balancer.....it is my experience that the higher class bearings, are expensive A small SKF (say 6002) or even smaller with no seals or shields, set up using green loctite on shafts & bores that are a "snug" slip fit should provide very little friction, considering the rollers are of a larger diameter and are concentric. Of course with"open bearings" cleanliness is the key. Jus' my two cents....anyway, it looks good Bruce & may your blocks never get "windowed" LOL

- RRBD

- Posts: 51

- Joined: Thu Apr 15, 2004 11:09 pm

- Location: MINNESOTA

9 posts

• Page 1 of 1

Return to Other DIY shop equipment

Who is online

Users browsing this forum: No registered users and 16 guests