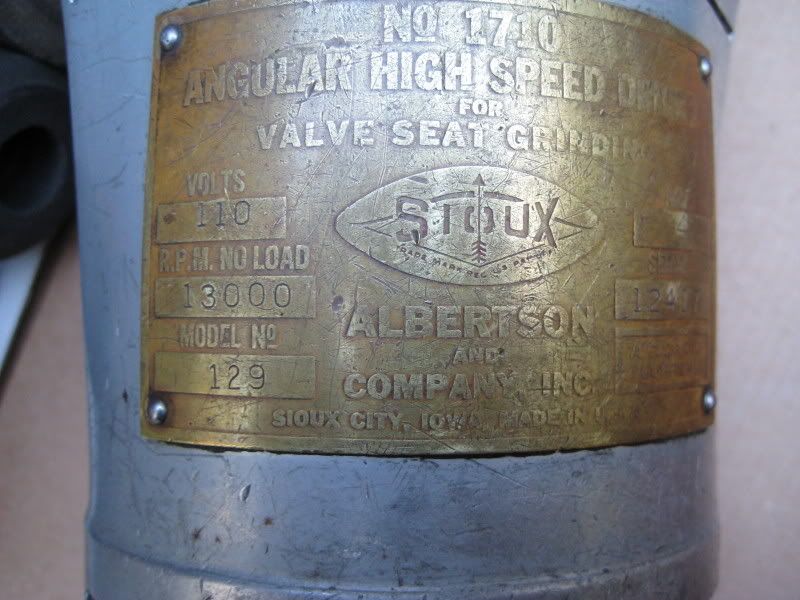

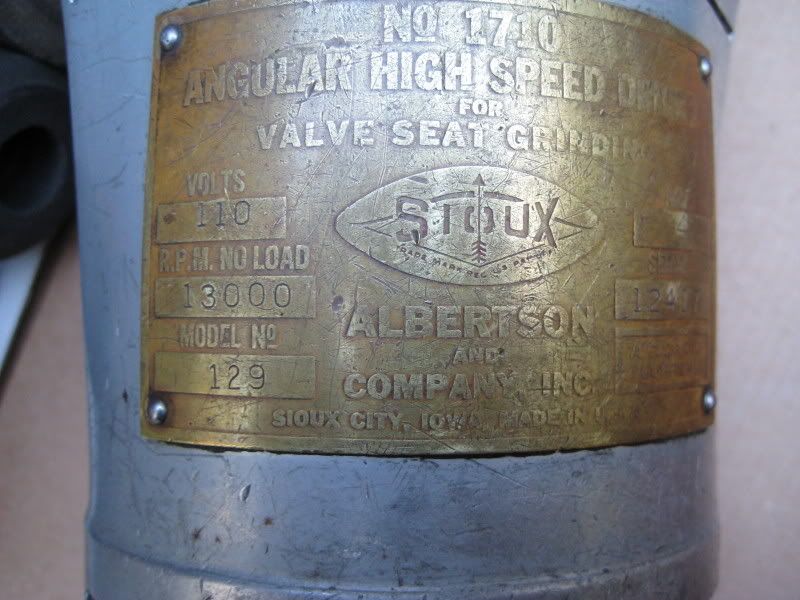

Valve Grinding Equipment

Tom,

Thats the tool you were looking for Did it have a Diamond in it?

You will use the standard Pink wheel like the link i sent for stainless valves. I am going down to the shop and will Mic the ID of some of the wheels i have (Old B&D stock) but if all else fails I know a machiniest named Bruce who might be able to make you a bushing.

Rick

Thats the tool you were looking for Did it have a Diamond in it?

You will use the standard Pink wheel like the link i sent for stainless valves. I am going down to the shop and will Mic the ID of some of the wheels i have (Old B&D stock) but if all else fails I know a machiniest named Bruce who might be able to make you a bushing.

Rick

- 49-1183904562

I used to be able to buy a B&D pink stone for by Sioux machine and I loved them. The Stellite stones that I used were white and seemed soft and wore in a hurry. Funny, to grind softer valves used a harder stone and to grind harder valves used a softer stone, hmmm. The butt facer side for the stem end was always a rougher gray stone from Sioux. I tried numerous stones there as you dealt with hard tips quite often. My best valve seat face was with the B&D pink stones and the Thinner Sunnen honing oil. As was mentioned you need to face the stone often. When it is grinding correctly it makes a smooth grinding sound. When the stone got dull it would chirp at you and would even leave a cupped surface.

John

John

- 106-1194218389

Tom,

I found another supplier on the web that posts B&D part numbers along with the new K-Line number

They are saying your 33056 B&D part is a 5/8 shaft can you Mic the shaft to be sure as I cannot find a stone with 7/16 shaft ID. That 100 grit GP stone looks nice the finest Goodson sels is 80.

Rick

I found another supplier on the web that posts B&D part numbers along with the new K-Line number

They are saying your 33056 B&D part is a 5/8 shaft can you Mic the shaft to be sure as I cannot find a stone with 7/16 shaft ID. That 100 grit GP stone looks nice the finest Goodson sels is 80.

Rick

- 49-1183904562

Getting closer to the number. It is actually 33058 lettering. And I notice they did not list the model: NWA

So apprently this is a very early machine. Yes, the shaft is definately 7/16. I tested a grind on a ruff intake. Gave about the same face grind as you saw on the exhaust. Then I went back and studied the wheel dresser. Yes, it has a point black rock set, wedged, pressed into the center of the pin, so that must be the black diamond. Then I played around with it again to figure out why it would not reach the wheel. Finally I got wise and reset the clamp bolt adjustor and it reached on over to the wheel. Cut the motor on, got the fluid flowing and carefully, very slowly walked it across the face width. Gave a very smooth cut across 3/4 ths of the diameter. Couldn't sweep the hold width but wider than before and left a much smoother surface. Didn't feel like 60 grit, perhaps the fluid smoothed it out. Will grind another junk valve tomorrow and see if the face is smoother.

Tomorrow I will call around and see if this older wheel still exists and if not perhaps go the bushing insert route. Will ask around on Speedtalk too since so many ProMachinists offer help there. It just might be the original wheel but it sure is small. Thanks so much for the help and guidance.

So apprently this is a very early machine. Yes, the shaft is definately 7/16. I tested a grind on a ruff intake. Gave about the same face grind as you saw on the exhaust. Then I went back and studied the wheel dresser. Yes, it has a point black rock set, wedged, pressed into the center of the pin, so that must be the black diamond. Then I played around with it again to figure out why it would not reach the wheel. Finally I got wise and reset the clamp bolt adjustor and it reached on over to the wheel. Cut the motor on, got the fluid flowing and carefully, very slowly walked it across the face width. Gave a very smooth cut across 3/4 ths of the diameter. Couldn't sweep the hold width but wider than before and left a much smoother surface. Didn't feel like 60 grit, perhaps the fluid smoothed it out. Will grind another junk valve tomorrow and see if the face is smoother.

Tomorrow I will call around and see if this older wheel still exists and if not perhaps go the bushing insert route. Will ask around on Speedtalk too since so many ProMachinists offer help there. It just might be the original wheel but it sure is small. Thanks so much for the help and guidance.

- 200cfm

- Posts: 302

- Joined: Fri Nov 17, 2006 10:52 pm

- Location: Virginia

Geee Guess i need some new reading glasses, If you need a bushing just let me know I can make you up a couple out of steel to fit the goodson wheels I use and the others. I checked the ones I had B&D .627 Kline .630 and Goodson .635. I will tell you I am going to see about ordering one of those 100 grit wheel as that would make a nice finish on the stainless valves I use.

Rick

Rick

- 49-1183904562

Tom,

I think the reason you cannot face the stone all the way across is that stone is just plain worn out. When mine would get too small in diameter I could not face all the way across. Since you are not going to do a lot of production work I would definately get the 100 grit stone if possible.

John

I think the reason you cannot face the stone all the way across is that stone is just plain worn out. When mine would get too small in diameter I could not face all the way across. Since you are not going to do a lot of production work I would definately get the 100 grit stone if possible.

John

- 106-1194218389

Ok, I found the problem on wheel arbor size and I stand corrected. I took some time to pull both wheels. The facer wheel had the paper on the back side not torn and tattered and the number was indeed 33056. And once I got the reverse thread nut off, behind the nut was a step for the arbor which is indeed 5/8ths. The wheel is a cup wheel design. Stem side wheel was a little different with a step up to 1/2" arbor and no cup.

Called Goodson and they have equivalent wheels in stock but tech said they were GP general purpose wheels.

Goodson recommended Orange wheel GV-146 for the valve refacer wheel and GV-145 for the stem wheel. The dimensions did match the shaft. Tech didn't know the grit on the orange wheel, just listed as GP and didn't see any grit code difference for a pink wheel, etc.. Asked about refacing oil and they offer only VGO-10, standard machining oil.

I will wait on this until I learn more about what the best grit should be. And will make another valve reface test on the old pink wheel that I redressed with the stone and got a much smoother surface. Just might be ok as is as long as my production is low.

Called Goodson and they have equivalent wheels in stock but tech said they were GP general purpose wheels.

Goodson recommended Orange wheel GV-146 for the valve refacer wheel and GV-145 for the stem wheel. The dimensions did match the shaft. Tech didn't know the grit on the orange wheel, just listed as GP and didn't see any grit code difference for a pink wheel, etc.. Asked about refacing oil and they offer only VGO-10, standard machining oil.

I will wait on this until I learn more about what the best grit should be. And will make another valve reface test on the old pink wheel that I redressed with the stone and got a much smoother surface. Just might be ok as is as long as my production is low.

- 200cfm

- Posts: 302

- Joined: Fri Nov 17, 2006 10:52 pm

- Location: Virginia

The ebay Sioux valve grinder has arrived. Much more stuff in the dirty old orange box compared to the Black & Decker stone driver. Lots of pilots, two drivers, lots of stones, some ok, some new, some shot. Motor runs fine. Everything was rather dirty and greasey so will clean it all up and see what I have. Best discovery is it has a Sious stone dresser. First time I have seen, touched, held a stone dresser. The B & D stone grinder had no pilots or stone dresser.

Question: When you dress a stone do you use grinding fluid or sweep it dry?

Kit also has a seat run out Starkett micrometer checker.

Question: When you dress a stone do you use grinding fluid or sweep it dry?

Kit also has a seat run out Starkett micrometer checker.

- 200cfm

- Posts: 302

- Joined: Fri Nov 17, 2006 10:52 pm

- Location: Virginia

[color=#000000]Tom,

True seat stones dry and if you can do it outside as they make a mess in the shop and a couple a grains of the Aluminum Oxide will play #### on anything of value, not to mention clean motor parts???

It sounds like you hit the jackpot with the Sioux auction, since you would be dealing with two different pilot sizes you may be better off just selling of the B&D stone set and recouping those funds for more stones and pilots for the Sioux setup .

.

You will also want to do two things when using stones One never grip the stone holder in the vice to get the stone off Never! as the next time you try to support the stone holder while it is spinning your palm wont feel so good. FYI when I grind seats I support the stone holder in one had and use the driver in the other letting spin lightly in my hand. Second to help you with number one, find (Sioux uses kind of a torx drive) either a torx bit or bolt that the stone holder will grab if inserted in the drive end then put that in the vise or weld it to a plate and screw it to the work bench this will allow you to hold the tone holder and use a strap wrench on the stone to remove it. The whole reason I am going over this is the stones will often get so tight in the holder you cant spin them off by hand and if you don

True seat stones dry and if you can do it outside as they make a mess in the shop and a couple a grains of the Aluminum Oxide will play #### on anything of value, not to mention clean motor parts???

It sounds like you hit the jackpot with the Sioux auction, since you would be dealing with two different pilot sizes you may be better off just selling of the B&D stone set and recouping those funds for more stones and pilots for the Sioux setup

You will also want to do two things when using stones One never grip the stone holder in the vice to get the stone off Never! as the next time you try to support the stone holder while it is spinning your palm wont feel so good. FYI when I grind seats I support the stone holder in one had and use the driver in the other letting spin lightly in my hand. Second to help you with number one, find (Sioux uses kind of a torx drive) either a torx bit or bolt that the stone holder will grab if inserted in the drive end then put that in the vise or weld it to a plate and screw it to the work bench this will allow you to hold the tone holder and use a strap wrench on the stone to remove it. The whole reason I am going over this is the stones will often get so tight in the holder you cant spin them off by hand and if you don

- 49-1183904562

Thanks, finished cleaning the Sioux today. Really impressed at the quality of the old stuff. Gunked, polished, and clean oil protected now. Some of the pilots go up to over 1/2". Definitely built to last a century. Has (5) 11/32 pilots from standard up to .004. Now I made a test fit and thought the .001 would fit in my guide. It didn't. The standard fits all the way down except for the last 3/8 of an inch. Then it starts to tighten and lock. I didn't force it further thinking I might bell mouth the guide. Does that mean it is a tapered 11/32 and is that normal. Once it locks or clamps I assume it is ready for the stone driver. Would that be correct?

I can't figure out what these two pieces go to. Look like some kind of attachment cutter but doesn't match up to anything. Anyone know?

The big Sious box not shown because it needs stripping and painting.

I can't figure out what these two pieces go to. Look like some kind of attachment cutter but doesn't match up to anything. Anyone know?

The big Sious box not shown because it needs stripping and painting.

- 200cfm

- Posts: 302

- Joined: Fri Nov 17, 2006 10:52 pm

- Location: Virginia

Yes, Tom that is correct. The bottom part of the pilot is tapered. That would be what I call a perfect fit. I like to see it in as far as it will go and be tight. Take a micrometer or even good dial calipers and check the top part of the pilot and make sure it is not worn or tapered too bad. Ideally it should be .385" all the way up. When the wear they start getting small at the top and then the stone holder will not run true and you get the seats starting to be out of round. btw I see you got a concentricity gauge with the setup. You got a very good deal on that.

John

John

- 106-1194218389

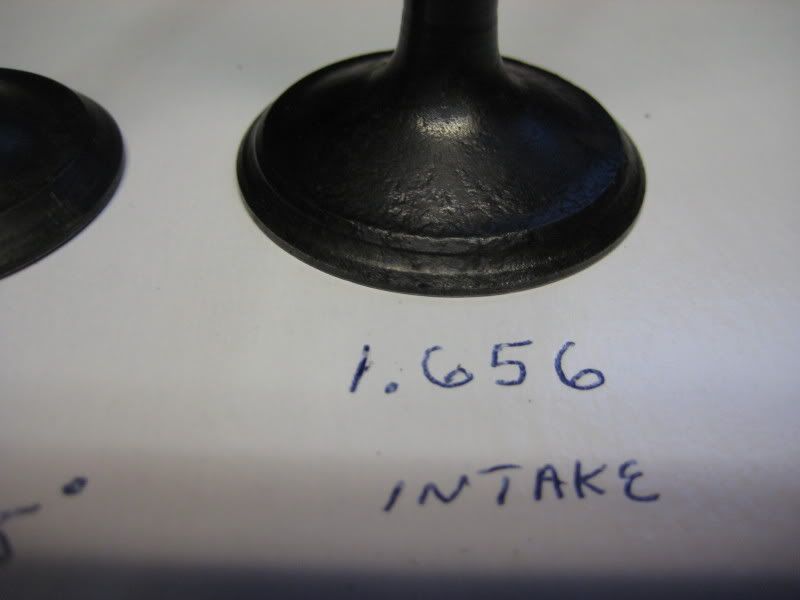

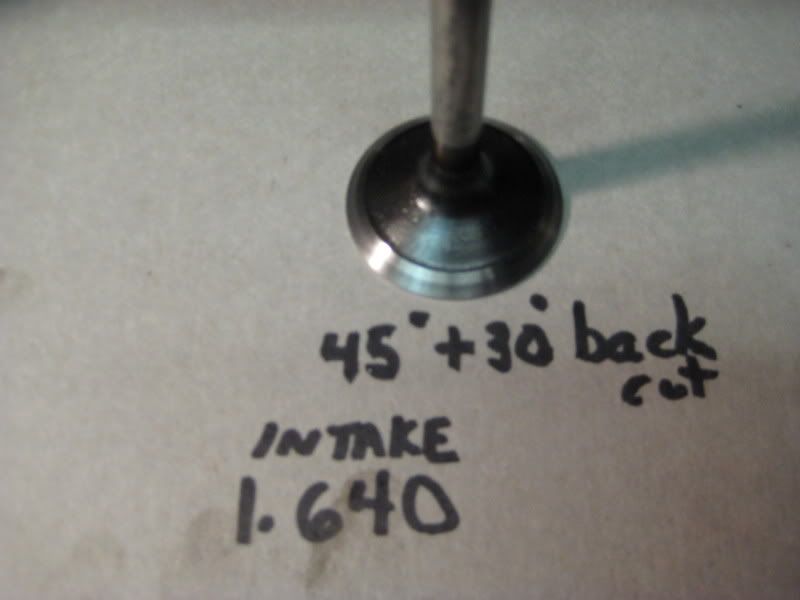

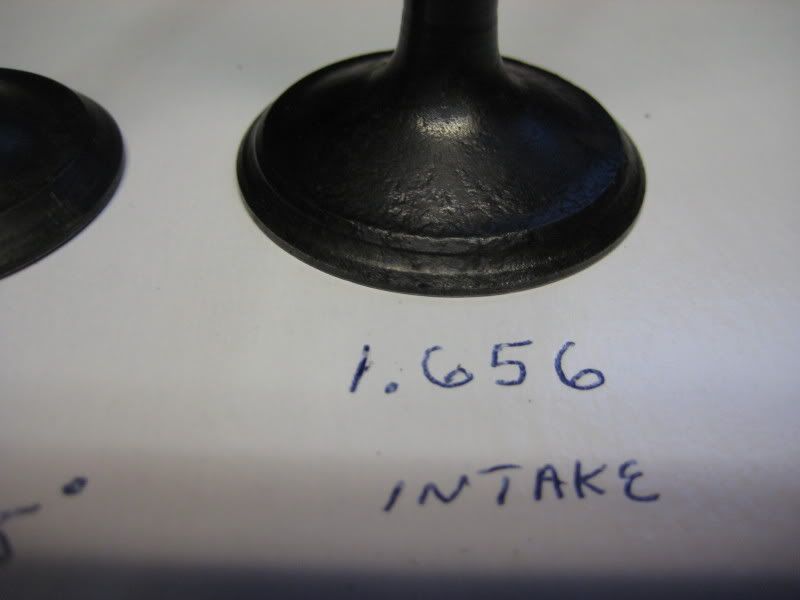

Here is a practice cut on an abused intake valve and trial cut 30 back cut.

45 reface

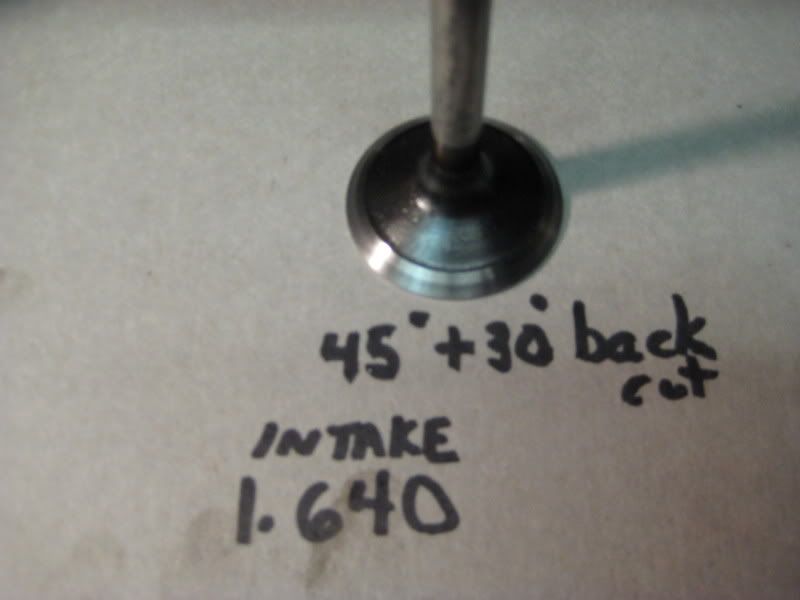

And the 30 degree backcut after dressing the stone. Much smoother.

I sent off an order to Goodson for new refacer and stem stones. And ordered one gallon of grinding oil that's suspose to flow clear in color. I couldn't find any information on the width of backcut margins. So I went about the same as the 45.

45 reface

And the 30 degree backcut after dressing the stone. Much smoother.

I sent off an order to Goodson for new refacer and stem stones. And ordered one gallon of grinding oil that's suspose to flow clear in color. I couldn't find any information on the width of backcut margins. So I went about the same as the 45.

- 200cfm

- Posts: 302

- Joined: Fri Nov 17, 2006 10:52 pm

- Location: Virginia

Return to Other DIY shop equipment

Who is online

Users browsing this forum: No registered users and 2 guests