Have any of you tried the BOUSFIELD VALVE SEAT CUTTER sold by Goodson. Reason i ask is it looks like a simple tool for the wekend racer to add to his bag of tricks.

Rick

Valve Grinding Equipment

Just as a hint for our UK members. There is a vintage valve grinding machine on ebay somewhere in Hampshire (look at auction 110439056649 ). It's local pick up only, very very dirty but still at 10 uk pound. So eventually it is a bargain for someone who can overhaul it.

(I have nothing to do with the seller, but I stepped over it, when looking for valve seat grinders)

Daniel

(I have nothing to do with the seller, but I stepped over it, when looking for valve seat grinders)

Daniel

- MrHijet

- Posts: 117

- Joined: Wed Aug 06, 2008 6:17 am

- Location: Dortmund, Germany

this is the first time using a hand held seat grinder, so I'm as green as you get :p

Trying to open up a intake port/seat from 1.88 to a 2.02.

I have been at it for almost a week now, a couple hours here and there. Going slow as to learn with out making to many ell reversible mistakes.

the seat, in the head, is enlarged to the point that the top of the 45* it now touching the bottom 45* of the 2.02 valve.

At this point, I'm afraid to go any farther, until i understand why this is happening.

Let me explain, every time i true up the stones and make my first cut..........they don't cut straight??? the stone that is!

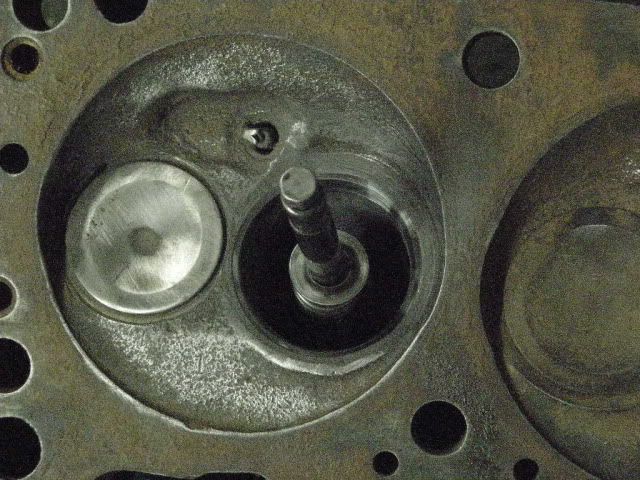

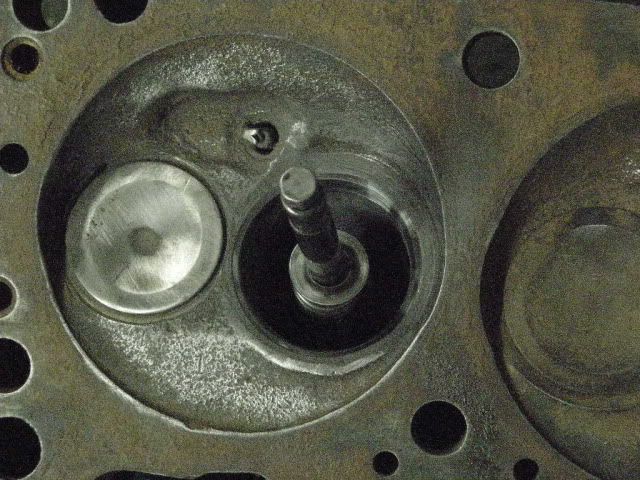

here is some pictures, that my help.

the first two pictures is freshly dressed stones that have had 30 sec of grind time on them...............Is this normal????

The pilot tool fits smug in the guide and then it has a nut on top, to expand it from there. It don't move.(these head have new bronze guide in them)

the guide to holder fits tight(although if you play with it for a minute, there is a ever so slight movement in it.)

am i just worrying over nothing!..............Or is this a BIG deal????

Thanks for all and any help you can give.

Trying to open up a intake port/seat from 1.88 to a 2.02.

I have been at it for almost a week now, a couple hours here and there. Going slow as to learn with out making to many ell reversible mistakes.

the seat, in the head, is enlarged to the point that the top of the 45* it now touching the bottom 45* of the 2.02 valve.

At this point, I'm afraid to go any farther, until i understand why this is happening.

Let me explain, every time i true up the stones and make my first cut..........they don't cut straight??? the stone that is!

here is some pictures, that my help.

the first two pictures is freshly dressed stones that have had 30 sec of grind time on them...............Is this normal????

The pilot tool fits smug in the guide and then it has a nut on top, to expand it from there. It don't move.(these head have new bronze guide in them)

the guide to holder fits tight(although if you play with it for a minute, there is a ever so slight movement in it.)

am i just worrying over nothing!..............Or is this a BIG deal????

Thanks for all and any help you can give.

Gordon

- Flash

- Posts: 285

- Joined: Sun Apr 26, 2009 1:23 pm

- Location: Evanston Wy

Personally, I don't like the idea of dead pilots, I've had far too many heads come in where people have used them and they haven't set up on the centre of the guide for whatever reason and everything they do from then on is not concentric.

saying that, I know they are a big thing in the US, I think Sunnen still uses them. In a perfect guide with a dead perpindicular spotface on it they are probably fine. I had a customer bring a head back to me because he checked the seat runout using this style of pilot and told me it was .005" out. It turned out his dead pilot was cocked over in the guide and the seat was actually spot on.

I've always used live pilots, you do need to have them in smaller increments but in both my repco and serdi machine they work brilliantly, I also use the same pilots for stones, the stone carriers I have have a grub screw that locks the pilot in place and it spins with the holder. I have carbide pilots for the common sizes and they are a step up again, just expensive if you drop them but they always run dead true and don't bend, also, some are 10 years old and not worn at all.

I know it's a matter of using what you have but it is pretty easy to turn up a stone carrier to take the stones you have and you end up with a really accurate setup. I rough the stones to size and shape with the diamond dresser and then finish them on the pilot I'm using in the valve facer, it makes for a perfectly sealing seat. I even finish the seats from the serdi with a stone just to make sure they're right.

saying that, I know they are a big thing in the US, I think Sunnen still uses them. In a perfect guide with a dead perpindicular spotface on it they are probably fine. I had a customer bring a head back to me because he checked the seat runout using this style of pilot and told me it was .005" out. It turned out his dead pilot was cocked over in the guide and the seat was actually spot on.

I've always used live pilots, you do need to have them in smaller increments but in both my repco and serdi machine they work brilliantly, I also use the same pilots for stones, the stone carriers I have have a grub screw that locks the pilot in place and it spins with the holder. I have carbide pilots for the common sizes and they are a step up again, just expensive if you drop them but they always run dead true and don't bend, also, some are 10 years old and not worn at all.

I know it's a matter of using what you have but it is pretty easy to turn up a stone carrier to take the stones you have and you end up with a really accurate setup. I rough the stones to size and shape with the diamond dresser and then finish them on the pilot I'm using in the valve facer, it makes for a perfectly sealing seat. I even finish the seats from the serdi with a stone just to make sure they're right.

- Greg

- Posts: 115

- Joined: Thu Jan 22, 2004 3:24 am

- Location: Queanbeyan, Australia

Gorden

Are you grinding the valve seat that's been replaced with a hardened seat?

I noticed two things about the stone.

1. the hardened seat material is stacking on the stone. You will need a different type of stone to cut the hardened seat.

2. the stone is only showing grinding shadow on part of the stone.

You keep dressing the stone and metal keeps building up on the stone. Once the metal stacks in the one spot the stone no longer runs on the seat.

Have you tried grinding a different seat with the same stone? Does it do the same thing?

Ray

Are you grinding the valve seat that's been replaced with a hardened seat?

I noticed two things about the stone.

1. the hardened seat material is stacking on the stone. You will need a different type of stone to cut the hardened seat.

2. the stone is only showing grinding shadow on part of the stone.

You keep dressing the stone and metal keeps building up on the stone. Once the metal stacks in the one spot the stone no longer runs on the seat.

Have you tried grinding a different seat with the same stone? Does it do the same thing?

Ray

"I know I'm in my own little world, but it's ok, they know me here"

- coulterracn

- Posts: 183

- Joined: Mon Jan 19, 2009 4:54 pm

- Location: Pascagoula, MS

Greg,Thanks for chiming in.

so, if I was to by a "live" pilot, my seat will come out true???/

what is the difference between a dead and live pilot?

What brand/model of these live pilots do you recommended?

another thing that bugs me. The the facing of these stones............

IF my stone holder was not made true or not centered, and my stone were not true either.....................the two off center pieces would become centered and true buy facing the stone......Right?

also if i use these "live pilots, would i need a new stone holder as well??????

so, if I was to by a "live" pilot, my seat will come out true???/

what is the difference between a dead and live pilot?

What brand/model of these live pilots do you recommended?

another thing that bugs me. The the facing of these stones............

IF my stone holder was not made true or not centered, and my stone were not true either.....................the two off center pieces would become centered and true buy facing the stone......Right?

also if i use these "live pilots, would i need a new stone holder as well??????

Gordon

- Flash

- Posts: 285

- Joined: Sun Apr 26, 2009 1:23 pm

- Location: Evanston Wy

Gordon, I have a very similiar problem. I found I was not removing enough material to actually seat the entire width of the margin on the valve face. Really showed up when I made a valve lap. The marking was not in the center of the valve face margin at all but ended up on the edge of the valve face backcut 45 to 30 line. I had thus an interference seal. To cure the problem I started bluing in the cuts and measuring the cut lines widths across the throat. Once I got the width of the valve diameter agreeing with the width of the stone bluing diameter the valve would drop in fine and lap ok.

I also find the stone has to be dressed fairly often to remove the contamination build up and not scratch mark the the seat cuts. It worked best for me to laydown the 45 seat first with a little extra margin. Then I would laydown the 30 top cut being careful not to take away to much of the margin from the 45. Then lay down the 60 cut, being careful to not take away to much of the 45 margin again. I finish the 45 with a fine stone touch up. Then lap the seat. So far they have passed the valve to seat seal liquid leak tests.

My guide is 11/32 diameter hole and I use the largest interfence pilot. I did learn that it has to be retapped in after every stone driver spin up because it would work loose. Loose pilot really screws things up.

The bushings in my stone drivers are worn. The end is the no longer available hex end. Sioux Star end # 1702 still available.

(tom c)

I also find the stone has to be dressed fairly often to remove the contamination build up and not scratch mark the the seat cuts. It worked best for me to laydown the 45 seat first with a little extra margin. Then I would laydown the 30 top cut being careful not to take away to much of the margin from the 45. Then lay down the 60 cut, being careful to not take away to much of the 45 margin again. I finish the 45 with a fine stone touch up. Then lap the seat. So far they have passed the valve to seat seal liquid leak tests.

My guide is 11/32 diameter hole and I use the largest interfence pilot. I did learn that it has to be retapped in after every stone driver spin up because it would work loose. Loose pilot really screws things up.

The bushings in my stone drivers are worn. The end is the no longer available hex end. Sioux Star end # 1702 still available.

(tom c)

- 200cfm

- Posts: 302

- Joined: Fri Nov 17, 2006 10:52 pm

- Location: Virginia

Does any one know if you can us Hex drive in star holder.

My driver is a Hex and i have one Hex and one Star holder.

the driver/ motor fits the star holder kinda loose........but then again the Hex holder is a loose fit for a reason...........................................

Any thoughts?

My driver is a Hex and i have one Hex and one Star holder.

the driver/ motor fits the star holder kinda loose........but then again the Hex holder is a loose fit for a reason...........................................

Any thoughts?

Gordon

- Flash

- Posts: 285

- Joined: Sun Apr 26, 2009 1:23 pm

- Location: Evanston Wy

Gordon, sorry, I didn't describe it well. A live pilot spins with the stone carrier or tool holder, like a serdi or newen machine uses. The carrier has a grub screw that locks the pilot in place so it spins with the stone. You need to lubricate the pilot in the guide but that's probably the only downside.

I suppose both can work well, I'm just comfortable with this setup and it lets me use the same pilots whether they're in the machine or a stone carrier. I use .375" top pilots which in Australia at least is the norm.

I can snap some photos if you like. Sorry, I read back through my post and it sounded a little condescending, I didn't intend it that way!

Cheers,

Greg

I suppose both can work well, I'm just comfortable with this setup and it lets me use the same pilots whether they're in the machine or a stone carrier. I use .375" top pilots which in Australia at least is the norm.

I can snap some photos if you like. Sorry, I read back through my post and it sounded a little condescending, I didn't intend it that way!

Cheers,

Greg

- Greg

- Posts: 115

- Joined: Thu Jan 22, 2004 3:24 am

- Location: Queanbeyan, Australia

Return to Other DIY shop equipment

Who is online

Users browsing this forum: No registered users and 12 guests