The software being within 5hp of a pro-stock engine is very impressive. The reason I asked about how well the software works is because it seemed to me that the amount of power you were seeing for the turbocharged engine was low, but that might have something to do with the efficiency of a two valve engine.

A stock Hayabusa pulls about 153hp at the back wheel but with 16 pounds of boost I've seen 300 rear wheel HP on mine so the correlation of pressure to power increase at that point is almost linear.

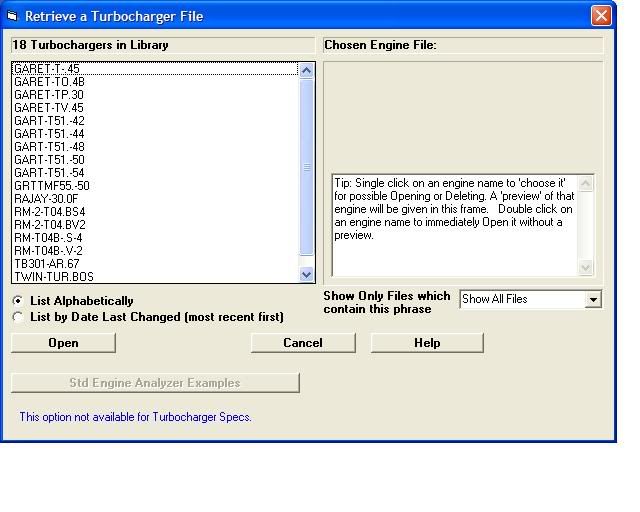

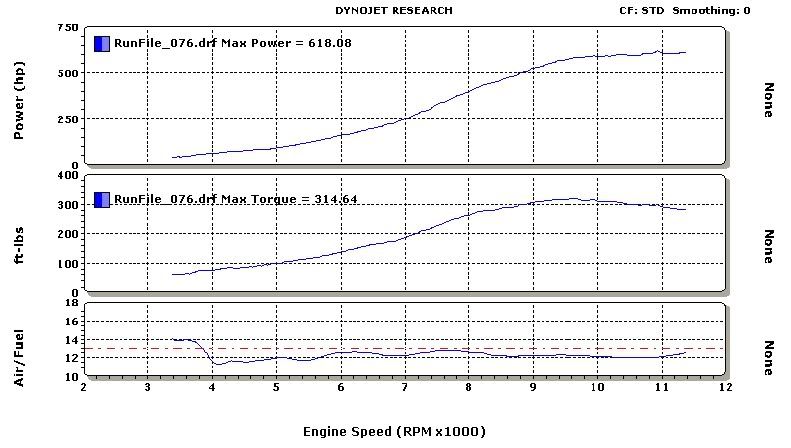

Regarding the inputs into your turbocharger field I would guess that the defaults are a reasonable starting point. Can you select a particular turbo from a list or do you have to put in all the specifics? If you have to put in the specifics it will be kind of a pain looking them up.

Here's an article I found that's a good starting point for understanding some of the fields in that input window: Here's a page with lots of different maps to look at:

Once you understand some of the basics of reading a turbo map then you can pull some of the numbers out - I assume that where it says island specs it is referring to the island of greatest efficiency - on the map in the article the middle of that island is at 20 pounds of air per minute which would work out to 289 cfm - very close to what is already entered - the pressure ratio of 1.8 is about the same too. I'm guessing that the maximum flow is the same as the choke area on the example which would be about 580 cfm on the example page. I'm not sure how they figure the surge cfm on your software because it is dependent on the pressure ratio.

I'd be interested in seeing what effects your software shows for different amounts of overlap and intake closing points with a turbo just to see how sensitive they are to those things.

200 CFM Research

I went back and did another run but this time I added an intercooler with 25% air to air efficiency. Quite the change! First test was without intercoolers:

with intercooler, my heads ported:

peak TQ = 809@3500 average TQ=540

peak HP = 674@5000 average HP=425

here are the choices the program provides:

with intercooler, my heads ported:

peak TQ = 809@3500 average TQ=540

peak HP = 674@5000 average HP=425

here are the choices the program provides:

It is a wise man that learns from his mistakes, but it is a wiser man that learns from the mistakes of others.

- jfholm

- Posts: 453

- Joined: Sat Jan 17, 2009 7:12 pm

- Location: Utah, USA

Yes, cooling the charge makes a huge difference not only for power but reliability too. The big problem on a lowered bike is finding a place to put the intercooler so a lot of drag and top speed racers are using ice coolers. I'd like one but either I'd have to fabricate a cooled plenum, which may be beyond my abilities, or I'd have to buy one and they go for big bucks. First I want to get my chassis working properly anyway.

On the turbo selection I'd think that a good starting point would be to find out what other guys are using and then go from there. You have to decide what the application is and how much boost will be used before making a selection. Is quick spool up time more important or peak power? Also, how much pressure can an engine take and for how long before depositing it's innards on the track?

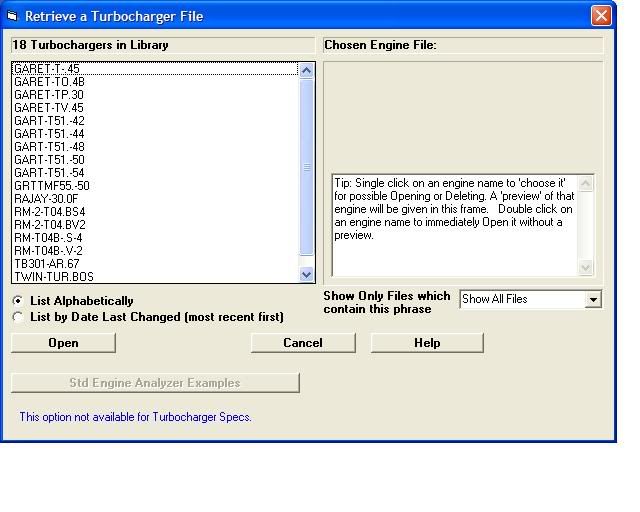

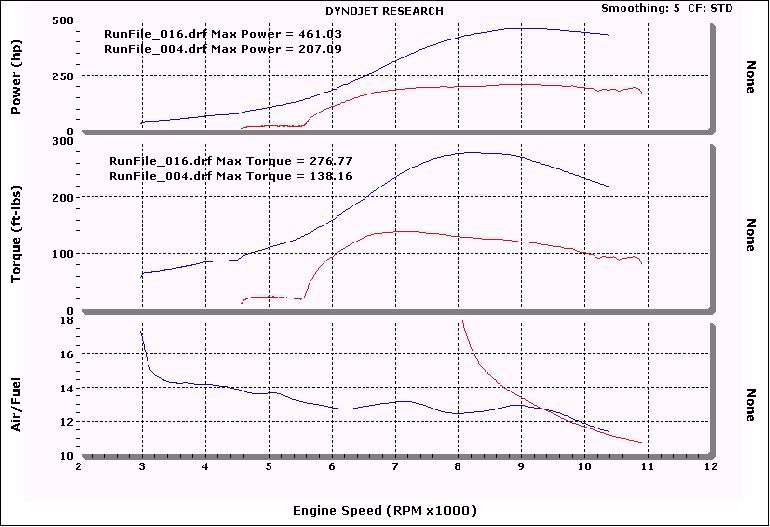

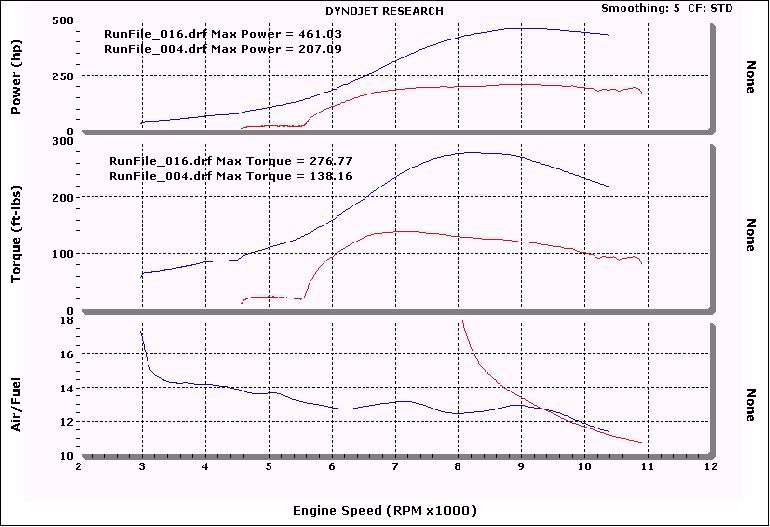

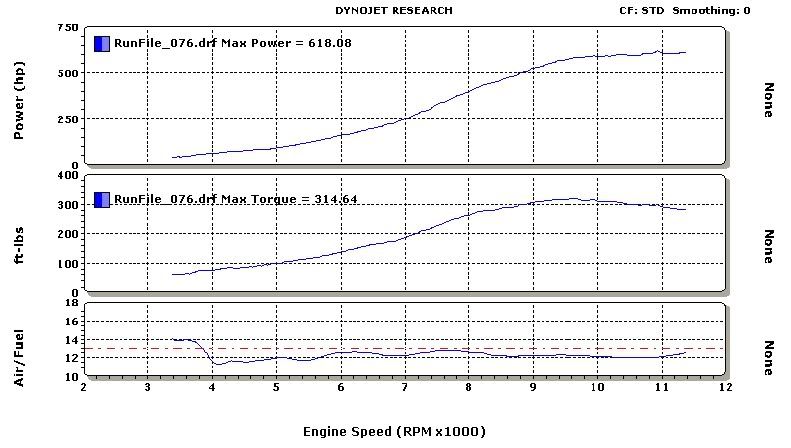

In the motorcycle world there are some guys putting car sized blowers on a bike. Here's a couple dyno sheets I found from Hayabusa motorcycles. Not too surprising that the greater peak power from the bigger turbo takes longer to build. I'd guess that the 600 hp sheet was probably running 40+ pounds of boost. Shows that you can almost mismatch the turbo and still get some crazy results if your willing to wait for the boost to build.

Not to shabby for a little 80 cubic inch engine though. I'm guessing that it makes for an interesting ride.

On the turbo selection I'd think that a good starting point would be to find out what other guys are using and then go from there. You have to decide what the application is and how much boost will be used before making a selection. Is quick spool up time more important or peak power? Also, how much pressure can an engine take and for how long before depositing it's innards on the track?

In the motorcycle world there are some guys putting car sized blowers on a bike. Here's a couple dyno sheets I found from Hayabusa motorcycles. Not too surprising that the greater peak power from the bigger turbo takes longer to build. I'd guess that the 600 hp sheet was probably running 40+ pounds of boost. Shows that you can almost mismatch the turbo and still get some crazy results if your willing to wait for the boost to build.

Not to shabby for a little 80 cubic inch engine though. I'm guessing that it makes for an interesting ride.

- emarsh

- Posts: 87

- Joined: Wed Apr 15, 2009 2:06 pm

Great postings, thanks. That S-3 trim map is the wheel I plan to upgrade too this fall. In EAP, is the turbine size referring to the exhaust or compressor side? I would think the compressor side.

When I model my current motor in Dyno Sim using my air flow data from the bench, cam specs. etc and a single turbo selection (TO4- V1) I get the following graph.

rpm hp tq

1500 89 311

2000 136 357

2500 186 391

3000 232 406

3500 280 420

4000 330 434

4500 378 441

5000 422 443

5500 455 434

6000 519 454

6500 540 436

7000 541 406

7500 528 369

It calculates the intake manifold pressure at 21.92 psi and Vol eff @ 118.8% on the 6500 rpm line. However, I don't run that much pressure. My gauge reads intake manifold pressure averaging 8 lbs boost. So if the carb drops say 1 or 1.5 lbs, the pressure at the top bonnet is close to 9-10 lbs.

Another odd observation is the peak rpm hp. It sets the cam as needing 6500 rpm to reach that goal, but I shift 5400 area and hit only 5700-5800 in the 1/8 trap and 6200-6300 in quarter trap. Appears I am shifting too soon.

The island flow on the Dyno Sim is set at 450 flow, 300 surge flow, and pressure ratio 2.0, peak island eff @ 75% , max boost 10 lbs. These values come up when V-1 is selected. I set the max boost value to 10. This is a single turbo menu but I think it is close to the smaller impeller twins I run which have 1.840 X 2.750 compressor wheels.

Probley not a perfect comparison because I suspect the twins would offer a few more lbs/min flow over a single V-1. (tom)

When I model my current motor in Dyno Sim using my air flow data from the bench, cam specs. etc and a single turbo selection (TO4- V1) I get the following graph.

rpm hp tq

1500 89 311

2000 136 357

2500 186 391

3000 232 406

3500 280 420

4000 330 434

4500 378 441

5000 422 443

5500 455 434

6000 519 454

6500 540 436

7000 541 406

7500 528 369

It calculates the intake manifold pressure at 21.92 psi and Vol eff @ 118.8% on the 6500 rpm line. However, I don't run that much pressure. My gauge reads intake manifold pressure averaging 8 lbs boost. So if the carb drops say 1 or 1.5 lbs, the pressure at the top bonnet is close to 9-10 lbs.

Another odd observation is the peak rpm hp. It sets the cam as needing 6500 rpm to reach that goal, but I shift 5400 area and hit only 5700-5800 in the 1/8 trap and 6200-6300 in quarter trap. Appears I am shifting too soon.

The island flow on the Dyno Sim is set at 450 flow, 300 surge flow, and pressure ratio 2.0, peak island eff @ 75% , max boost 10 lbs. These values come up when V-1 is selected. I set the max boost value to 10. This is a single turbo menu but I think it is close to the smaller impeller twins I run which have 1.840 X 2.750 compressor wheels.

Probley not a perfect comparison because I suspect the twins would offer a few more lbs/min flow over a single V-1. (tom)

- 200cfm

- Posts: 302

- Joined: Fri Nov 17, 2006 10:52 pm

- Location: Virginia

That dyno sim software sounds really cool - I guess I'll have to get a copy as soon as I have a couple of extra $$$.

Just for the sake of interest, here's a few photos of a Hayabusa motorcycle head. At this point I'm thinking that when my bench is done I'll put a junker head on it for the sake of curiosity, but it looks like a pretty well designed head and I don't expect that I won't find too much room for big improvements. But then again, I won't know until I try. Perhaps some work to unshroud the valves a bit will be beneficial.

Just for the sake of interest, here's a few photos of a Hayabusa motorcycle head. At this point I'm thinking that when my bench is done I'll put a junker head on it for the sake of curiosity, but it looks like a pretty well designed head and I don't expect that I won't find too much room for big improvements. But then again, I won't know until I try. Perhaps some work to unshroud the valves a bit will be beneficial.

- emarsh

- Posts: 87

- Joined: Wed Apr 15, 2009 2:06 pm

I thought about starting a new thread with this.........But this is such a good thread, and......this fits right in!

A new pitot idea or design..........called a "P-D Valve"( Pressure diferenal Valve)

did a search on here, and found nothing, so i'm guessing this is somthing new to ponder on

A new pitot idea or design..........called a "P-D Valve"( Pressure diferenal Valve)

did a search on here, and found nothing, so i'm guessing this is somthing new to ponder on

Gordon

- Flash

- Posts: 285

- Joined: Sun Apr 26, 2009 1:23 pm

- Location: Evanston Wy

Thanks for responding Bruce.

Yeah, that crossed my mind as well.........

and it does not help in the short side radius were the flow is the trickiest to figure out.

Thought it was interesting and worth throwing out there for discussion :O

Yeah, that crossed my mind as well.........

and it does not help in the short side radius were the flow is the trickiest to figure out.

Thought it was interesting and worth throwing out there for discussion :O

Gordon

- Flash

- Posts: 285

- Joined: Sun Apr 26, 2009 1:23 pm

- Location: Evanston Wy

Hum, looks like EAP would want data input from the compressor side as much as the hot side. That's the side that moves and heats up the air and there are lots of trim choices.

John, my book calls for standard hot side turbine wheel as having 2.296" inducer and 2.922 major. Try that number in EAP turbine input data. I am measuring pretty close to those numbers with my import mics.

John sent me a draft of EAP printout on my current motor being raced. It shows slightly less turbine exhaust pressure than boost pressure. 5.6 psi back pressure at 6k on 6.5 avg boost setting or 1.48 compressor pressure ratio.

HP came in at 480 at 6 k. He ran their ET pro calculator program and it hit close to my best 1/4 time. It predicted 10.25 @ 131.9. Close to pipemax prediction and pipmax showed a over rev and fueling support issue beyond the 1100 mark. What's a safe exhaust temperture range?

What version John are you using? I checked their website and 3.3 is available with more improvements. (tom c)

John, my book calls for standard hot side turbine wheel as having 2.296" inducer and 2.922 major. Try that number in EAP turbine input data. I am measuring pretty close to those numbers with my import mics.

John sent me a draft of EAP printout on my current motor being raced. It shows slightly less turbine exhaust pressure than boost pressure. 5.6 psi back pressure at 6k on 6.5 avg boost setting or 1.48 compressor pressure ratio.

HP came in at 480 at 6 k. He ran their ET pro calculator program and it hit close to my best 1/4 time. It predicted 10.25 @ 131.9. Close to pipemax prediction and pipmax showed a over rev and fueling support issue beyond the 1100 mark. What's a safe exhaust temperture range?

What version John are you using? I checked their website and 3.3 is available with more improvements. (tom c)

- 200cfm

- Posts: 302

- Joined: Fri Nov 17, 2006 10:52 pm

- Location: Virginia

I am using the latest 3.5 of EAP. I will run it at 15 pounds and see what it does.

Tom,

do you have room for intercoolers?

John

Tom,

do you have room for intercoolers?

John

It is a wise man that learns from his mistakes, but it is a wiser man that learns from the mistakes of others.

- jfholm

- Posts: 453

- Joined: Sat Jan 17, 2009 7:12 pm

- Location: Utah, USA

Who is online

Users browsing this forum: No registered users and 1 guest