The divider wall is the wall betwee ports. It's usually straightest of the two port walls. In most cases you only have to worry about the head bolt hole protrusion.

I have used JB Weld (original not quik-set) to repair heads and blocks with good results. The block I'm running now was cracked between the lifter valley and water circulation opening in the deck. I drilled through the block at the end of the crack and ground a gruve along the crack from outside to inside the block. I filled it with JB Weld and let it cure with a 100 watt bulb in a reflective shield fixture. That was in the mid 80's.

Ray

Porting a Chy 340/360 head.

thanks Ray,

Well laying back the ssr and widening it, a lot on the prp wall.

Tried to smooth any bump i could find.

resoles?

Well, compared to my best cfm #### lost 7cfm a .100 -6@.200 Match @.300 - 2@.400 - 2@.500 and +1@.600

This is the first time that .600 cfm was higher then .500.

I have my max cfm back........but it's at .600 lift

compared to the low # when i messed up the seat. I had 20+ cfm more all the way too .600 lift.

My choke was enlarged do to short 75*cut. And when i roled back the ssr, it opened up the choke csa enlarger...................at least that my theory on the .600 lift starting to flow now.

Sound is better, no tire screeching sound.

fps port tells me the ssr has slowed, almost to much265-350(Compaired to the 398-444 i started out with)

but mid port and roof has increased.

the vary top of the roof wouldn't hold even 100 cfm now is a 199

Clay experimentation is the only port work i will be doing on this port from here.

Well laying back the ssr and widening it, a lot on the prp wall.

Tried to smooth any bump i could find.

resoles?

Well, compared to my best cfm #### lost 7cfm a .100 -6@.200 Match @.300 - 2@.400 - 2@.500 and +1@.600

This is the first time that .600 cfm was higher then .500.

I have my max cfm back........but it's at .600 lift

compared to the low # when i messed up the seat. I had 20+ cfm more all the way too .600 lift.

My choke was enlarged do to short 75*cut. And when i roled back the ssr, it opened up the choke csa enlarger...................at least that my theory on the .600 lift starting to flow now.

Sound is better, no tire screeching sound.

fps port tells me the ssr has slowed, almost to much265-350(Compaired to the 398-444 i started out with)

but mid port and roof has increased.

the vary top of the roof wouldn't hold even 100 cfm now is a 199

Clay experimentation is the only port work i will be doing on this port from here.

Gordon

- Flash

- Posts: 285

- Joined: Sun Apr 26, 2009 1:23 pm

- Location: Evanston Wy

Flash just follow the instructions that is what I did & when

I did it turn a olive green or close to that color worked

out for me very good.

I levee it dry for 48 hours @ 72 degrees I do not want to

take a chance.

I filled holes about 1/4" make sure you get some worked back in

around the back side of the hole to help hold it in there. Then

I pressure tested the head it held & has been on that engine

for five years now with out a leak.

Malvin

I did it turn a olive green or close to that color worked

out for me very good.

I levee it dry for 48 hours @ 72 degrees I do not want to

take a chance.

I filled holes about 1/4" make sure you get some worked back in

around the back side of the hole to help hold it in there. Then

I pressure tested the head it held & has been on that engine

for five years now with out a leak.

Malvin

- Malvin

- Posts: 93

- Joined: Thu Nov 22, 2007 10:39 am

- Location: Central Pennsylvania

Thanks Malvin!

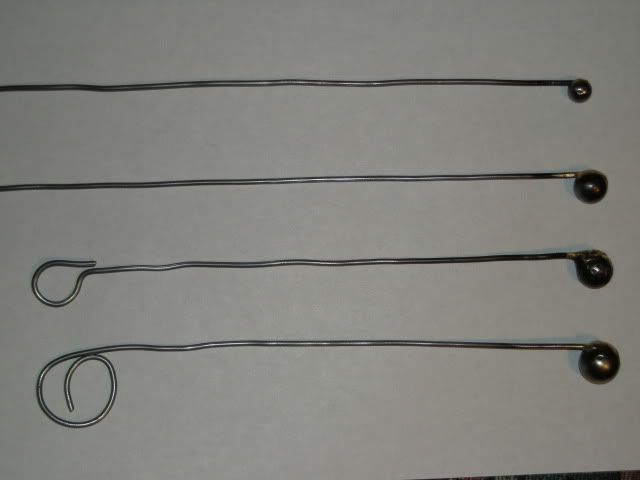

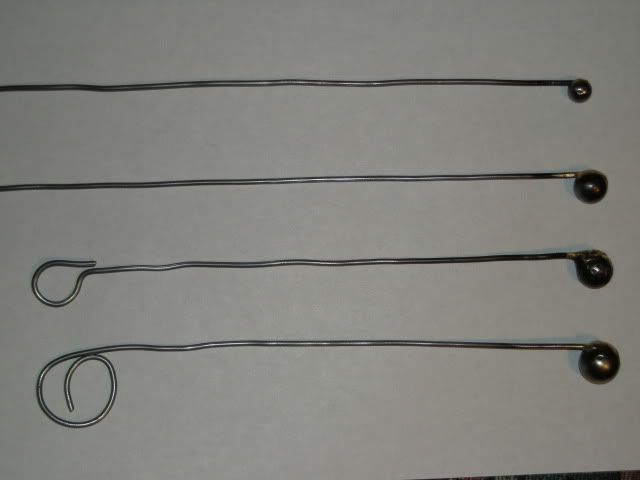

Well, after reading Tom's thread,and Larry's post/link to the "Flow Balls"

I decide to make me a primitive set of flow balls.

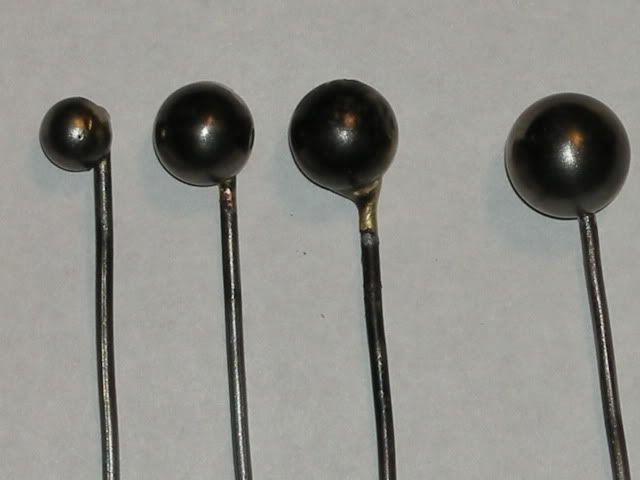

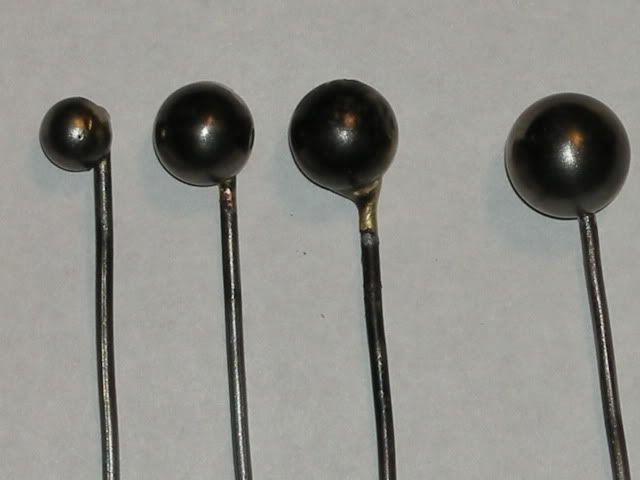

I made mine out of some old ball bearings and the smallest one came form a carburetor kit. The wire, is a larger diameter, mechanic's wire. Think I'm going to make me one more that's even smaller. the smallest one, float in the are stream, in some places.

This make a much better picture of were the air is going. Much better then the FPS probe..........But then again, the the ball would slam to either wall but didn't like the center..... went, Hmmmm wonder what the fps is in that area

Here is another idea, for those that, want to try and build one.

remember the "Blow Dart guns" you had as a kid.

the wire would flex a lot, but not bend like mechanic's wire.

the balls would flow much better in the air stream then steel or lead...........

Any ways it was vary interesting to watch the ball move along the floor of the port like a snake!

Enter the port, it went to the, non prp wall. An inch in, it go's to center. a faction more and it slams up agenced the prp wall.

As i go farther into the port, it centers up and head straight for the fastest fps point of ssr.

Now, I have no clue, how to apply this to my port. But after i get some more play time with these, and start mapping the direction of the air, and at what height,..........I thing i will experiment some more with clay.(don't dare grind much more on this port.......It's to large any ways!)

My largest ball, made vary little difference(good or bad) threw most of the port.

My next port, i will be attacking, from a hole different direction.

Man i have so much to learn............Just to be able to call my self a "Educated IDIOT" :p

Well, after reading Tom's thread,and Larry's post/link to the "Flow Balls"

I decide to make me a primitive set of flow balls.

I made mine out of some old ball bearings and the smallest one came form a carburetor kit. The wire, is a larger diameter, mechanic's wire. Think I'm going to make me one more that's even smaller. the smallest one, float in the are stream, in some places.

This make a much better picture of were the air is going. Much better then the FPS probe..........But then again, the the ball would slam to either wall but didn't like the center..... went, Hmmmm wonder what the fps is in that area

Here is another idea, for those that, want to try and build one.

remember the "Blow Dart guns" you had as a kid.

the wire would flex a lot, but not bend like mechanic's wire.

the balls would flow much better in the air stream then steel or lead...........

Any ways it was vary interesting to watch the ball move along the floor of the port like a snake!

Enter the port, it went to the, non prp wall. An inch in, it go's to center. a faction more and it slams up agenced the prp wall.

As i go farther into the port, it centers up and head straight for the fastest fps point of ssr.

Now, I have no clue, how to apply this to my port. But after i get some more play time with these, and start mapping the direction of the air, and at what height,..........I thing i will experiment some more with clay.(don't dare grind much more on this port.......It's to large any ways!)

My largest ball, made vary little difference(good or bad) threw most of the port.

My next port, i will be attacking, from a hole different direction.

Man i have so much to learn............Just to be able to call my self a "Educated IDIOT" :p

Gordon

- Flash

- Posts: 285

- Joined: Sun Apr 26, 2009 1:23 pm

- Location: Evanston Wy

Who is online

Users browsing this forum: No registered users and 1 guest