I have already carried out some experiments here trying to discover a really simple way to construct a blower outer housing that combines ultra low cost and extreme simplicity of construction.

Commercial blowers all use the familiar scroll shaped outer casing, which is really a bit of a nuisance to fabricate. Yet vacuum cleaner motors seem to work reasonably well with a simple really crude round outer drum shaped casing.

Apart from the shape, there are two other fundamental requirements. It must be strong enough to withstand the considerable air pressures involved, and it absolutely must have a readily removable front cover to install and access the rotor.

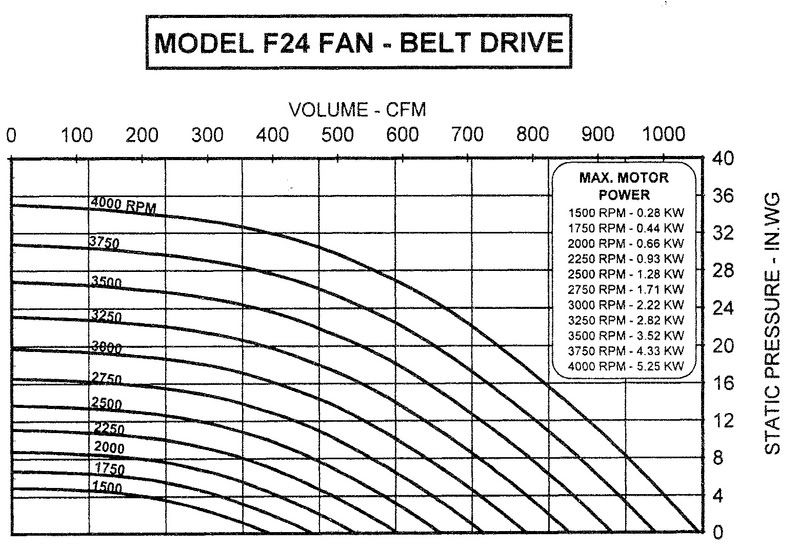

What I decided to do, was first carry out some tests on a commercial belt driven high pressure blower, and then remove the original outer scroll housing, and replace it with a cut down 55 gallon drum. The original scroll was 24 inches diameter across the widest section, the new drum 23 inches diameter.

Everything else would remain exactly the same, same rotor, same drive motor, but I could do some careful back to back tests against a dumb drum housing and directly compare the results. I honestly did not expect it to work as well as it did.

Cutting straight through to the final results, my conclusion is that a round drum works perfectly well, and the flow and pressure figures that I measured were identical to that of a really sexy sculptured volute shape. It need be made no larger either.

I will go into more precise details of this later, but here are pictures of the original commercial Aerotech blower, and after it had been fitted with my ugly drum housing.