Page 1 of 1

Posted:

Sat Oct 03, 2009 3:24 pmby lrader99

picked up an old GE 4 speed motor with an 11" squirrel cage for the amazing price of FREE. motor says 115v 6 amp 60 hz 1000RPM. it uses a coil to start the motor. im assuming this 1000 RPM is on HIGH. can anyone give an estimate on the amount of airflow.

thanks a bunch

Posted:

Sun Oct 04, 2009 12:11 pmby thomasvaught-1

Squirrel Cage Blowers do an excellent job of moving LARGE quantities of air through a furnace system. Typically they do

a poor job as a flow bench motor as you need a certain amount of test pressure across the tested part, (Head, Carb, etc).

Most people would like to test in the 28" of water depression range. Most squirrel cage blowers will barely generate 1/4th

that test pressure. I would use that unit in your paint booth

and move on to a different type of Flow bench motor strategy.

Tom Vaught

Posted:

Sun Oct 04, 2009 10:18 pmby lrader99

thats fine im planning to build a booth soon anyway, so thats one part out of the way.

Posted:

Mon Oct 05, 2009 2:38 amby Tony

Tom is right.

If your blower casing looks something like a beer barrel driven by a motor, it should have tons of airflow, and most likely develop really wimpy pressure.

If your blower casing has the profile of a cookie, huge diameter, but a really anorexically skinny casing, with a "several" or "many" horsepower drive motor, you may have found an an ideal pressure blower for a flow bench.

Posted:

Mon Oct 05, 2009 10:47 amby lrader99

just have to keep my eyes open...i have the barrel. which i will use to cool the shop and eventually for the paint booth

Posted:

Tue Oct 06, 2009 12:18 amby fast_crew

Posted:

Tue Oct 06, 2009 2:45 amby Tony

Josh, these blowers are usually referred to as "pressure blowers" .

They sometimes turn up on e-bay, and sometimes can be spotted at machinery junk yards and turn up at auctions. It is a case of recognising something when you see it.

They are mainly used for industrial processes that require a lot of pressure such as sand blasting, and transferring dry products along pipes.

You might be looking for something about three feet in diameter with a four inch diameter inlet, and three inch diameter outlet with perhaps a 3 to 5Hp motor. Price varies a lot, but $200 to $300 would be ball park.

But these sometimes go for much less. They are fairly obscure items, and not sough after. Difficult to find, but even harder to sell.

A low ball offer could possibly get you a magnificent flow bench blower for peanuts, but you may need to be a little patient, and just keep your eyes open for a while..

Posted:

Tue Oct 06, 2009 8:35 pmby Malvin

Tony

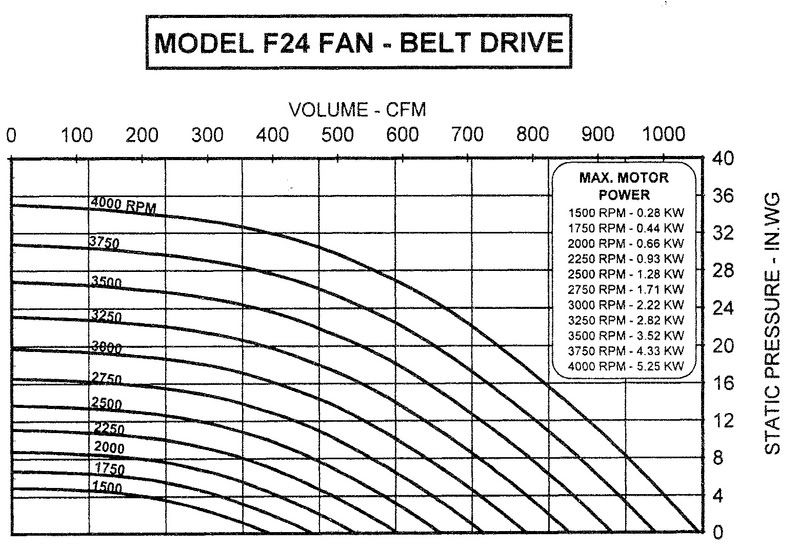

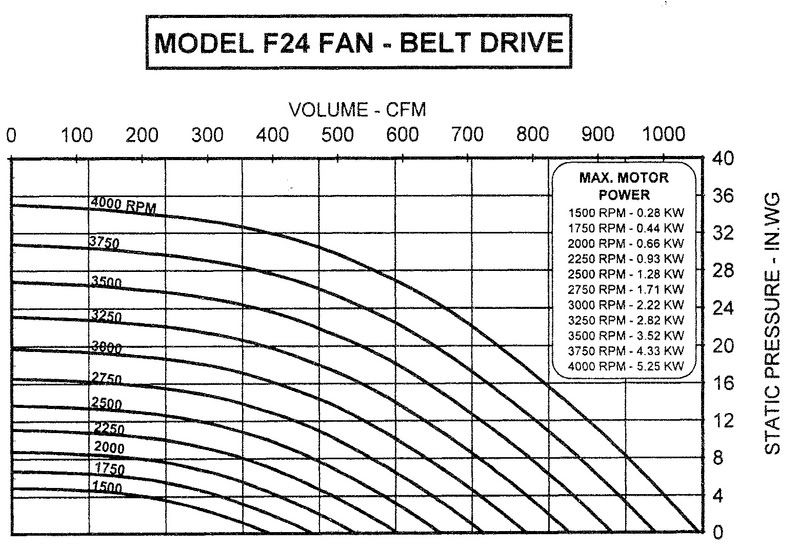

Is this inline with what you are talking about?

Spec sheet link

Malvin

Posted:

Wed Oct 07, 2009 2:50 amby Tony

Yes Malvin, EXACTLY

The pictures are an excellent guide, and the performance curves and dimensions even better, for the type of thing to be looking out for.

The trick is being able to recognise a rusty old unloved pressure blower sitting forlornly in a junk yard, as being pure gold, just by the dimensions.

Pretend to be really disappointed, it is not at all what you want, make the guy a really low ball offer, and maybe get your perfect blower for a song.

The cost of a brand new one will probably freak you out, but they very often go second hand, for virtually scrap value. There is almost no demand for these blowers.

The thing to realize, is that a particular blower may look a bit small if run at the original 50/60 Hz with the original motor fitted to it.

But with a VFD you can run it up to 75Hz or 95 Hz or even more.

With a much more powerful motor fitted, and a VFD, both pressure and flow with a given blower size can be increased hugely.

For instance, a particular blower may run at 60 Hz and have a 3Hp motor fitted when you buy the blower.

If you run it up to 90Hz, flow will increase almost x1.5, and pressure will be up around x 2.25, and horsepower perhaps x3.375.

A 10Hp replacement motor might do very nicely.

Even a 15 Hp replacement motor if you have the power to run one.

It may sound optimistic replacing a 3Hp motor with a 15 Hp motor.

But a few extra rpm increase, requires some really serious torque to spin that sucker up a bit more.

Hp increases with the CUBE of the rpm increase !

A direct drive blower will overall, be smaller, have less vibration and NO DRIVE BELT PROBLEMS, when you drastically increase the drive horsepower and speed.

A pulley driven blower can usually be converted to direct drive.

With a VFD pullies are no advantage, and for me, have been an absolute curse.

Much better to bolt the rotor straight onto the motor shaft, and then use a VFD to control it, as well as get any required extra speed increase.

Posted:

Wed Oct 07, 2009 11:23 pmby Malvin

Tony can I ask if you are using one of these blowers just how

big is your flow bench in size??

I should call my buddy that works at a Dog food plant he tells

me they have them High Pressure blowers to move dry dog food

product from one end of the plant to the other end through a 12"

ID pipe. Last time we talked he said he could get me one of these High Pressure blowers cheap.

Malvin

Posted:

Thu Oct 08, 2009 3:21 amby Tony

My flow bench uses a pressure blower that has an eighteen inch rotor, in a two foot diameter outer casing. It is rather on the small side for both flow and pressure.

Originally it came with a 1.5 Hp motor. but I now run it at twice the original speed with a 10Hp motor, and 2:1 pulley drive.

Here are some fan curves for that blower.

The original 2850 rpm 1.5 Hp motor created roughly 17" of pressure at maybe 250 CFM. Run up to 5,000 blower rpm with 10 Hp, and a 2:1 pulley ratio, I can easily now get well over 55" at 500+ CFM.

But the pulley drive system slips on acceleration, and is the worst feature of what I now have. There should probably be about five drive belts, not two, (or a toothed belt drive). Even better would be to just direct couple the motor, and run it up to 100Hz with my VFD. That would sure beat running it at 50Hz with the awful pulley system.

Direct drive is absolutely the better method.

Yes, I can well believe a pressure blower is used to shift dry dog food. I have seen them used to move peanuts and cornflakes down long pipes in large manufacturing plants.

My own blower with a two foot outer casing diameter is a bit small, three feet with around a 24 inch diameter rotor would be better, and three feet is not a bad bench height for a flow bench.

Such a blower would fall nicely into our pressure range requirements without having to significantly over speed the motor.

Posted:

Thu Oct 08, 2009 3:46 amby Malvin

Thats a nice looking Flow Bench Tony!!

I think I am going to build a Third flow bench using one

of these high pressure blowers I did call my buddy to see

if he still had that high pressure blower from the dog food

plant but he was not home I will have to call him on the

weekend about it.

Thanks Tony

Malvin