Turbocharger as air mover?

14 posts

• Page 1 of 1

As I have mentioned before, I have a Roots blower from a Detroit 8V92 which I planned to convert to my air mover. Since then I realized the turbocharger from the same engine may be a better choice. The turbo is about 20 years old but in excellent shape. I have been unable to find a compressor map for the same model, which is a Garrett with the Detroit OEM #8927027, part #466570-0001 (Garrett?). In any case, I found this more modern model, the GT4718, with the correct inducer and exducer diameter. My compressor housing has an A/R of .81 but my guess is the performance on the attached compressor match is reasonably close? The turbine section would be sacrificed but I am inquiring as to ideas to drive this unit to the rpm's required? 600 cfm should be in the 40'ish pound of flow rate area but the pressure would be below the existing map islands. I imagine something with router like motor speeds would work, although several hp would be needed. Any input appreciated.

- 2seater

- Posts: 106

- Joined: Thu Sep 23, 2004 9:18 pm

The pressure developed will be very roughly proportional to tip speed squared.

An 18" rotor might need to spin at about roughly 3,600 rpm to generate 28" of pressure (1 psi).

A 1.8" diameter turbo sized rotor would need to spin up to 36,000 Rpm to generate a similar pressure. The relationship is not exact, but it is very close.

Most routers seem to work somewhere around 20,000 rpm.

Half the rpm only gets you one quarter the pressure, which will not be enough.

Much better to go the other way and use a large diameter rotor running at a sane speed. My own bench has a pulley driven industrial pressure blower with an 18" rotor, and I can run it up to almost 5,000 rpm flat out, to reach 50".

If you look at some of these industrial pressure blowers, you will quickly see how crude the construction is inside, and how very easy it would be to build one yourself from scratch.

Or you can probably rescue one from a machinery junk yard fairly cheaply.

Something like that will give you all the air you could wish for, run silently at good efficiency, and last a lifetime without any problems at all.

An 18" rotor might need to spin at about roughly 3,600 rpm to generate 28" of pressure (1 psi).

A 1.8" diameter turbo sized rotor would need to spin up to 36,000 Rpm to generate a similar pressure. The relationship is not exact, but it is very close.

Most routers seem to work somewhere around 20,000 rpm.

Half the rpm only gets you one quarter the pressure, which will not be enough.

Much better to go the other way and use a large diameter rotor running at a sane speed. My own bench has a pulley driven industrial pressure blower with an 18" rotor, and I can run it up to almost 5,000 rpm flat out, to reach 50".

If you look at some of these industrial pressure blowers, you will quickly see how crude the construction is inside, and how very easy it would be to build one yourself from scratch.

Or you can probably rescue one from a machinery junk yard fairly cheaply.

Something like that will give you all the air you could wish for, run silently at good efficiency, and last a lifetime without any problems at all.

Also known as the infamous "Warpspeed" on some other Forums.

- Tony

- Posts: 824

- Joined: Sat Dec 03, 2005 12:34 pm

- Location: Melbourne, Australia

[color=#000000]Tony is right the blower can be built,as you can see this rotor is a very easy design and not hard to build. this one is at a junkyard they are asking 300 euros for it. If they don

- racehead-1

- Posts: 30

- Joined: Mon Mar 10, 2008 7:29 am

- Location: Portugal

Thanks guys. This is a very large turbo with a tip diameter over 4.5", but I do realize it will still take a lot of rpm. The compressor map shows about 50# of air (~700cfm) @ ~ 7psi where the 77% efficiency lines and 45,000 rpm intersect. I have found high speed (24,000 rpm) 5-7hp motors are available, but details as to cost and the variable frequency drive are open. I have considered the large homemade blower as pictured also, and it has it's attraction as well. The low speed and ability to drive it with pretty standard stuff are certainly strong points. Just trying to use parts I already have.

- 2seater

- Posts: 106

- Joined: Thu Sep 23, 2004 9:18 pm

o/k 4.5 inches is four times smaller than 18 inches. My guess would be :

3,600 rpm = 1.875 inches of pressure

7,200 rpm = 7.5 inches pressure

14,400 rpm = 30 inches pressure

28,800 rpm = 120 inches pressure

11,000 rpm = 175 cfm

22,000 rpm = 350 cfm

45,000 rpm = 700 cfm.

A 20,000 rpm router driving this might get you about 55 inches of pressure and perhaps 315 cfm of flow as a wild guess.

At 24,000 rpm maybe 83 inches (3 psi) of pressure at 373 cfm that is about 4.9 air horsepower. The drive motor will probably need to be about twice that, assuming 50% efficiency..

Motor power rises cubed law with rpm.

It only needs to be slowed down slightly and a much less powerful motor will work fine.

3,600 rpm = 1.875 inches of pressure

7,200 rpm = 7.5 inches pressure

14,400 rpm = 30 inches pressure

28,800 rpm = 120 inches pressure

11,000 rpm = 175 cfm

22,000 rpm = 350 cfm

45,000 rpm = 700 cfm.

A 20,000 rpm router driving this might get you about 55 inches of pressure and perhaps 315 cfm of flow as a wild guess.

At 24,000 rpm maybe 83 inches (3 psi) of pressure at 373 cfm that is about 4.9 air horsepower. The drive motor will probably need to be about twice that, assuming 50% efficiency..

Motor power rises cubed law with rpm.

It only needs to be slowed down slightly and a much less powerful motor will work fine.

Also known as the infamous "Warpspeed" on some other Forums.

- Tony

- Posts: 824

- Joined: Sat Dec 03, 2005 12:34 pm

- Location: Melbourne, Australia

Thanks Tony. You're wild guesses are generally pretty good so that helps me greatly in my decision making. The pressure would be nice but the flow rate looks too low unless I was just flowing heads, and I can come close to that now with the gaggle of vacuum motors. The big centrifugal is looking more attractive. Much appreciated.

- 2seater

- Posts: 106

- Joined: Thu Sep 23, 2004 9:18 pm

You could always mount two of those rotors back to back on the same shaft, and have a dual inlet centrifugal blower.

That would double the flow, and double the drive horsepower.

That would double the flow, and double the drive horsepower.

Also known as the infamous "Warpspeed" on some other Forums.

- Tony

- Posts: 824

- Joined: Sat Dec 03, 2005 12:34 pm

- Location: Melbourne, Australia

Interesting idea, but I don't have two matching compressor wheels. It would be spinning backwards in any case. I do have the next size smaller complete turbo also, with a 4.32" o.d. wheel but trying to duplicate the nice tight clearances in a homemade housing. I am warming up to the large low speed blower as a better alternative. I am not sure what I laying around for sheet metal to make a rotor. What would be suitable? I am pretty sure I have a piece of 16 ga. stainless but it would be pretty heavy and a pain to work with. Thanks for the input.

- 2seater

- Posts: 106

- Joined: Thu Sep 23, 2004 9:18 pm

Here is a typical commercial rotor.

The rear is just a flat sheet mild steel disc bolted onto a taper lock hub.

There are ten short straight blades pop riveted to this disc.

And a flared non stressed, (very thin) front cover pop riveted to the blades.

This rotor is eighteen inches in diameter. The blades are seven inches long and 5/8 inch wide. The central intake "eye" is five and a uphalf inches in diameter.

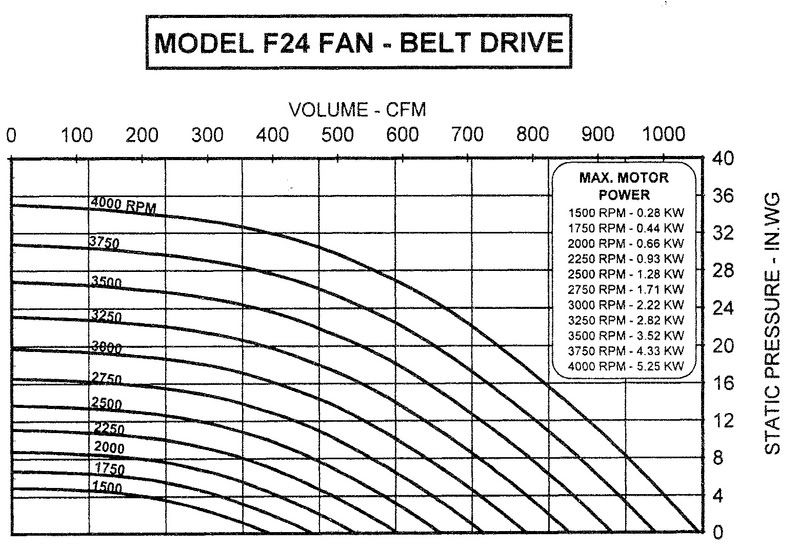

Here are the blower curves for that specific rotor. At 4,000 rpm you can reach around thirty inches at 500 cfm. Even higher speed can generate some serious pressure, at even higher flows. Note how the curves spread further apart with increased rpm. This is the square law pressure effect.

This is just an example of what could be done. Very simple construction, nothing that a hobbyist could not duplicate, or improve upon.

One advantage of these big blowers is that if you were running at say 4,000 rpm with your thirty inches, and the flow suddenly completely blocks due to an accident, the blocked flow pressure goes up to only thirty six inches.

With typical high rpm vacuum motors, the blocked flow pressure can spike up to 120+ inches, and potentially burst or implode your bench. These big blowers are much safer in that regard.

Also known as the infamous "Warpspeed" on some other Forums.

- Tony

- Posts: 824

- Joined: Sat Dec 03, 2005 12:34 pm

- Location: Melbourne, Australia

I am liking the big rotor more and more. I will have to look around for materials. I lost my access to all the sheet metal and forming equipment when I lost my job, but I have some stuff "in stock". To be honest, I had printed out the thread on the large blower you had posted some time ago and I really appreciate the details.. The other stuff I have would probably work in some form, but the more conventional approach looks like a better option.

- 2seater

- Posts: 106

- Joined: Thu Sep 23, 2004 9:18 pm

If you are not burning with impatience, just keep an eye out on e-bay, and go for a scrounge around some of the machinery grave yards in your area,

With a bit of thought, (and a calculator), it is possible to tell pretty much just by looking what any blower is capable of just from the rotor diameter and motor rpm (pressure), and flow, from the motor rated horsepower.

For our needs, we require a large diameter skinny blower, with the proportions of a biscuit. And inlets/outlets roughly in the three to five inch diameter range. About the same size as your test hole will be about right.

With a bit of thought, (and a calculator), it is possible to tell pretty much just by looking what any blower is capable of just from the rotor diameter and motor rpm (pressure), and flow, from the motor rated horsepower.

For our needs, we require a large diameter skinny blower, with the proportions of a biscuit. And inlets/outlets roughly in the three to five inch diameter range. About the same size as your test hole will be about right.

Also known as the infamous "Warpspeed" on some other Forums.

- Tony

- Posts: 824

- Joined: Sat Dec 03, 2005 12:34 pm

- Location: Melbourne, Australia

Thanks for the advice. As soon as the winter loosens its grip I think I will poke around some. I am not in any sort of rush. Money is one issue, but I have a bench that works now and I am only looking for something to make it more efficient, and quieter.

- 2seater

- Posts: 106

- Joined: Thu Sep 23, 2004 9:18 pm

One day you will spot something, or stumble onto a suitable blower unexpectedly, and for maybe two to three hundred dollars. These obscure blowers are difficult to find, but even more difficult to sell.

Don't appear too enthusiastic and you could get a real bargain.

There is a " Buffalo pressure blower" on e-bay right now, but at $1,300 (no bids) is a bit steep.

It does however produce 6,000 CFM flow, and 28 inches, and has a 40 Hp motor.

Far too large for us, but it shows what can sometimes turn up.

To get an idea of size, pallets are usually around three feet square.

Don't appear too enthusiastic and you could get a real bargain.

There is a " Buffalo pressure blower" on e-bay right now, but at $1,300 (no bids) is a bit steep.

It does however produce 6,000 CFM flow, and 28 inches, and has a 40 Hp motor.

Far too large for us, but it shows what can sometimes turn up.

To get an idea of size, pallets are usually around three feet square.

Also known as the infamous "Warpspeed" on some other Forums.

- Tony

- Posts: 824

- Joined: Sat Dec 03, 2005 12:34 pm

- Location: Melbourne, Australia

14 posts

• Page 1 of 1

Who is online

Users browsing this forum: No registered users and 2 guests